Novel Heat-Management Material Keeps Computers Running Cool

The H-Lab

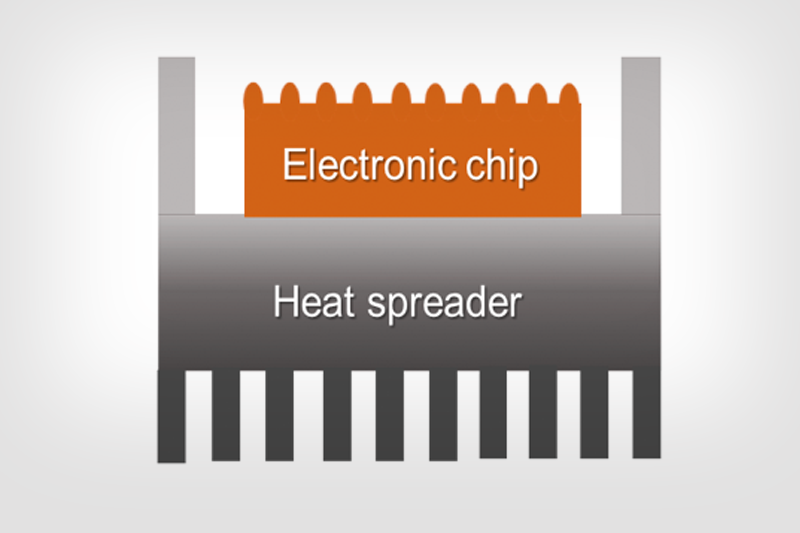

Schematic illustrating thermal management in electronics chip packaging

UCLA engineers have demonstrated successful integration of a novel semiconductor material into high-power computer chips to reduce heat on processors and improve their performance. The advance greatly increases energy efficiency in computers and enables heat removal beyond the best thermal-management devices currently available.

The research was led by Yongjie Hu, an associate professor of mechanical and aerospace engineering at the UCLA Samueli School of Engineering. Nature Electronics recently published the finding in this article.

In order to solve the problem, Hu and his team had pioneered the development of a new ultrahigh thermal-management material in 2018. The researchers developed defect-free boron arsenide in their lab and found it to be much more effective in drawing and dissipating heat than other known metal or semiconductor materials such as diamond and silicon carbide. Now, for the first time, the team has successfully demonstrated the material’s effectiveness by integrating it into high-power devices.

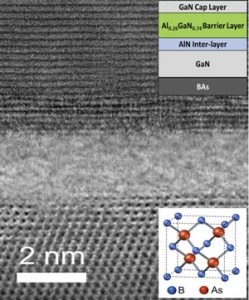

In their experiments, the researchers used computer chips with state-of-the-art, wide bandgap transistors made of gallium nitride called high-electron-mobility transistors (HEMTs). When running the processors at near maximum capacity, chips that used boron arsenide as a heat spreader showed a maximum heat increase from room temperatures to nearly 188 degrees Fahrenheit. This is significantly lower than chips using diamond to spread heat, with temperatures rising to approximately 278 degrees Fahrenheit, or the ones with silicon carbide showing a heat increase to about 332 degrees Fahrenheit.

According to Hu, boron arsenide is ideal for heat management because it not only exhibits excellent thermal conductivity but also displays low heat-transport resistance.

“When heat crosses a boundary from one material to another, there’s typically some slowdown to get into the next material,” Hu said. “The key feature in our boron arsenide material is its very low thermal- boundary resistance. This is sort of like if the heat just needs to step over a curb, versus jumping a hurdle.”

The team has also developed boron phosphide as another excellent heat-spreader candidate. During their experiments, the researchers first illustrated the way to build a semiconductor structure using boron arsenide and then integrated the material into a HEMT-chip design. The successful demonstration opens up a path for industry adoption of the technology.

In addition to Hu, other co-lead authors on the paper are UCLA graduate students and members of his research group Joon Sang Kang, Man Li, Huan Wu and Huuduy Nguyen. Co-author Toshihiro Aoki of the Irvine Materials Research Institute also contributed to the study, conducting microscopy measurements.

The research was supported by the Watanabe Excellence in Research Award; the Alfred P. Sloan Foundation; the National Science Foundation; the U.S. Air Force Office of Scientific Research; the Sustainable LA Grand Challenge; and the Anthony and Jeanne Pritzker Family Foundation. The team also used computational and storage services provided by the UCLA Institute for Digital Research and Education’s Research Technology Group, and the Extreme Science and Engineering Discovery Environment (XSEDE), which is supported by the National Science Foundation.