Breakthrough could lead to deformable aircraft wings, new types of body armor

UCLA mechanical engineers have developed a new class of materials that can dramatically change their shape while still retaining their stiffness.

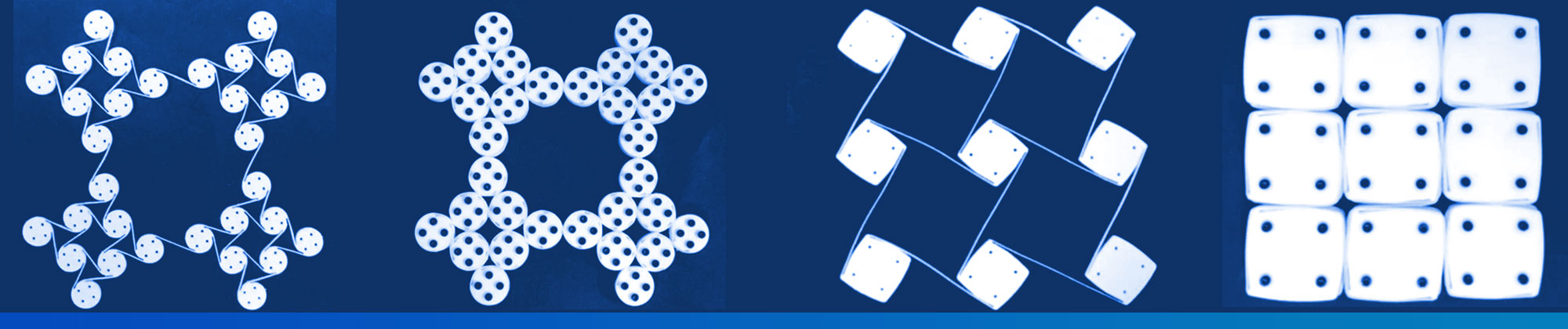

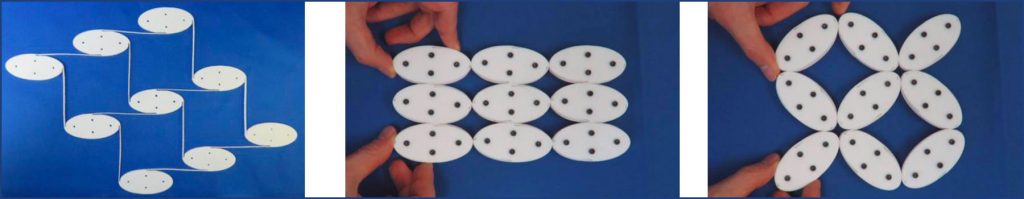

These materials are based on building block structures called “compliant rolling-contact joints.” These joints work in similar ways to a how a retractable tape measure works – a tense strap loops around a shape. Sometimes several straps surround the shape. While these compliant joints are not new, the group, from the UCLA Samueli School of Engineering, is the first to use them together to form lattices that are then used to build 2D and 3D shape-shifting materials.

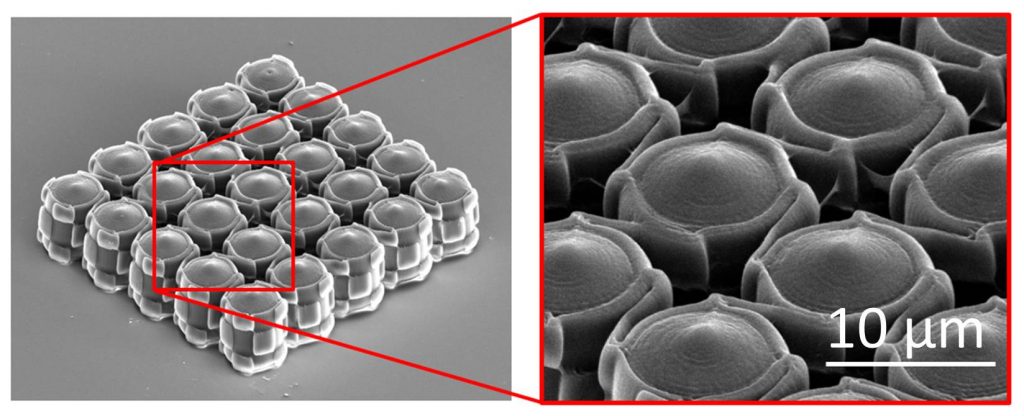

The researchers demonstrated the versatility of the new material with several computer simulations, as well as built-out mechanisms that can be manipulated by hand. They also created microscopic mechanisms. The research was published in Nature Communications.

“Unlike other shape reconfigurable metamaterial designs that tend to fail beyond small ranges of deformation, the materials we introduce here can change shape over huge ranges without much increase in their internal stress,” said Jonathan Hopkins, an assistant professor of mechanical and aerospace engineering and the principal investigator on the research. “The materials we are designing can be made to occupy any initial shape and can deform to any other desired shape. One example could be an aircraft wing that changes its shape over a large range, but needs very little actuation energy and still retains high stiffness throughout its deformation.”

Such materials could also be shaped to control how stress waves propagate inside a material and could lead to new body and vehicle armor; acoustic lenses that focus sound for underwater or medical imaging technologies; or sound-scrambling technologies for privacy applications.

Authors on the paper included postdoctoral scholars Lucas Shaw and Yuangping Song, graduate student Samira Chizari, and recent bachelor’s degree graduate Matthew Dotson. All are members of Hopkins’ research group.

The team also created a software program available free of cost for people to design their own shape-changing materials using this concept.

The research was supported by the Air Force Office of Scientific Research and the Department of Energy through the Presidential Early Career Award for Scientists and Engineers. Chizari is supported by a National Science Foundation Graduate Research Fellowship.