Bioengineers Develop Spider Web-Inspired Method to Fabricate Conductive Fibers

Advance could lead to energy-efficient, low-cost smart textiles

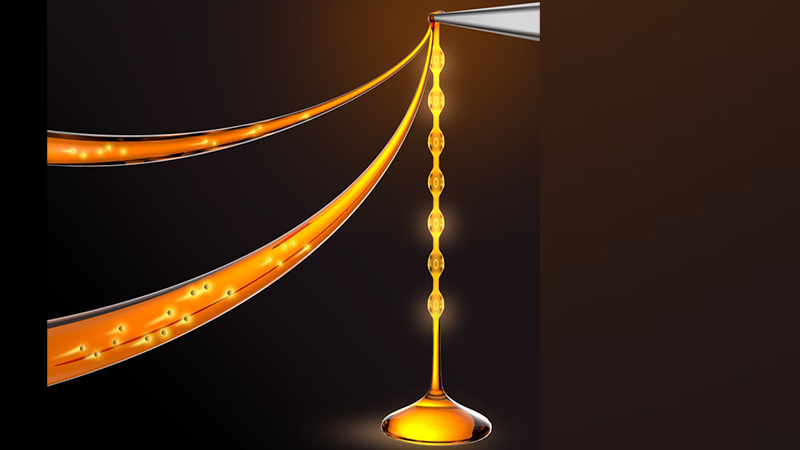

Jun Chen/UCLA

An illustration showing a spider web-inspired process to produce conductive fibers

Using a new process that mimics how spiders spin silk, a UCLA-led team of multi-institutional bioengineers has developed a simple process to make soft, electrically conductive fibers at room temperature and atmospheric pressure.

In a study published as a cover story in Nature Electronics, the researchers demonstrated their technique with a sensing glove and a smart face mask made with the stretchable and durable fabrics. The glove can sense temperatures and hand motions for the user to play a “rock-paper-scissors” computer game, while the mask is able to monitor the individual’s breathing patterns.

Existing methods to make electrically conductive fibers are costly and complex requiring high temperatures, energy consumption, volumes of solvents and specialized fiber-spinning equipment.

“We wanted to develop a highly efficient and cost-effective manufacturing process for electrically conductive fibers that can be much easier to implement, mirroring state-of-the-art processes that make conductive 2D sheets and 3D objects,” said co-corresponding author Jun Chen, an assistant professor of bioengineering at the UCLA Samueli School of Engineering. “With this new approach, we can create conductive soft fibers with high efficiency at a low cost.”

The fibers are made from polyacrylonitrile —a type of a synthetic polymer — and silver ions, which provide the fibers with their electrically conductive properties. The combined ingredients are then dissolved in dimethylformamide, or DMF, a common solvent used in the production of synthetic fibers.

“We wanted to develop a highly efficient and cost-effective manufacturing process for electrically conductive fibers that can be much easier to implement, mirroring state-of-the-art processes that make conductive 2D sheets and 3D objects,” said co-corresponding author Jun Chen.

To help water vapor from the surrounding air pull out the liquid solvent, the solution is spun on a spinning plate, creating a network of polyacrylonitrile molecules and silver ions, dubbed PANSIon by the researchers. Stretchy, free-standing fibers of PANSion can then be extracted from the plate in less than a minute. This action is similar to how spiders make webs by spinning liquid proteins into silk threads. The resulting fibers are similar to rubber in stretchiness and are as strong as cotton fiber.

According to the researchers, their fibers offer strong electrical conductivity that can sense respiration, temperature and touch. When used in smart textiles, the fibers can have energy, sensing and therapeutic applications, such as a surgical-style mask that tracks breathing throughout the night for someone with sleep apnea.

The first author on the research is Songlin Zhang, a former postdoctoral scholar in Chen’s Wearable Bioelectronics Research Group at UCLA who is now with the National University of Singapore.

Other UCLA authors are Yihao Zhou, Alberto Libanori and Xun Zhao — all current and former members of Chen’s research group. Additional authors are from the National University of Singapore, as well as Nanjing University and Jilin University in China.

The research was supported by startup funding from UCLA Samueli, a Hellman Fellows Research Grant, a UCLA Pandemic Resources Program Research Award and a Research Recovery Grant from the UCLA Academic Senate. Additional support came from the Brain & Behavior Research Foundation and the West Coast Consortium for Technology & Innovation in Pediatrics at Children’s Hospital Los Angeles.