New Flexible Polymer Hydrogel Electrode Makes for Improved Bioelectronics

Advance can lead to better-performing personalized diagnostic and treatment devices

The He Lab/UCLA

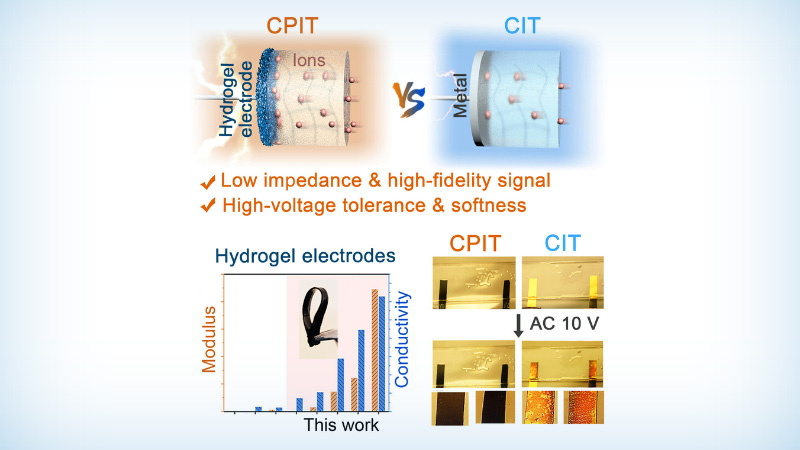

Schematics of conducting-polymer-assisted ionotronics (CPIT) with conducting polymer hydrogel as the electrode (top left) and common ionotronics (CIT) with metal as the electrode (top right). CPIT shows a lower electrode-electrolyte interface impedance, a lower interfacial voltage for more sustainable operations and a more stable signal transmission ability.

UCLA Samueli Newsroom

UCLA materials engineers designed a hydrogel electrode that could help advance bioelectronics that require direct tissue contact for health monitoring and therapies, such as pacemakers or high-sensitivity neural probes used to diagnose diseases including Alzheimer’s and epilepsy.

Soft and flexible, the hydrogel is surprisingly strong and exhibits high conductivity and can be easily fabricated and replace metals currently used in a variety of advanced biological devices. Led by materials science and engineering associate professor Ximin He of the UCLA Samueli School of Engineering, the research was recently published in Matter and could fundamentally change the way biological systems interact with machines.

Relying on electric signals that activate regions of the brain, humans have been able to interact with and think about the world around them. These signals result from ions — electrically charged atoms or molecules — that transport packages of electrons from one part of the body to another.

Electronic devices, on the other hand, utilize inorganic and conductive materials to move electrons, similar to how mail was delivered via pneumatic tubes through compressed air in the old days.

In order for machines to more readily interface with biological systems for advanced biotechnologies, there needs to be ionotronic devices that can convert between electron and ion transport systems at the electrode and tissue interface — a process called electron-ion transduction,

Up until now, metals have been commonly used in electrodes for ionotronics. However, such electron-ion transduction is significantly impeded and can be very sensitive to changes in voltage. To overcome this hurdle, He’s team designed an ionotronic electrode using a conductive polymer hydrogel that decreased the impedance and improved the voltage tolerance of an ionotronic device.

“As personalized health care and wearable devices rapidly advance, it opens up unprecedented opportunities for diagnosis and therapeutics, such as telerobotic surgery, implantable devices of longer lifetime and high accuracy, and more comfortable and long-term monitoring of brain or muscle signals that can even be done at home,” He said. “These demands call for new soft materials that can better interface biological systems and manmade electrical devices. This new hydrogel material offers a very promising path for improved interfaces.”

According to He, the conductive polymer hydrogel design of the electrode balances high mechanical strength and low impedance in a soft material by incorporating a strong polymer network with interconnected nanosized pores. The polymer network reinforces the structure of the electrode and the numerous pores provide more room for electron-ion transduction as well as storage for the converted electrons. The electronic storage capabilities of the new electrode also eliminate the use of metal to collect current while improving biocompatibility.

In its research, the group showed that ionotronic devices that use a hydrogel interface over a metal one exhibit improved efficiency and stability by orders of magnitude. The hydrogel electrode was more voltage-tolerant, transduced a signal more consistently and has a long-term stability not inherent in metal electrodes.

To further improve the hydrogel’s performance, the researchers developed a processing technique called surface gelation that reinforces the outer layers of the hydrogel through electrostatic interactions with iron microparticles. This highly tunable process allows the researchers to have precise control over the size, shape and location of the pores in the material.

The researchers found that the new material can be a game changer in designing physiological signal detectors, tactile sensors and artificial muscles. By incorporating the hydrogel as a conductor, bioelectronic devices such as pacemakers could have a longer lifetime and would require fewer surgeries for the users to replace the battery. Soft robots using the material would be more stable and shapeable. Earbuds and speakers embedded with the hydrogel could have improved sound quality due to the material’s excellent signal-transmission performance.

Dr. Tzung Hsiai, a professor of medicine and bioengineering who holds the Maud Cady Guthman Chair in Cardiology in the David Geffen School of Medicine at UCLA is the other senior author on the paper. The co-lead authors of the paper are postdoctoral researcher Bowen Yao and Ph.D. candidate Yichen Yan, both of whom are members of He’s research lab. Other authors are UCLA bioengineering postdoctoral researcher Qingyu Cui and additional members from He’s lab — Sidi Duan, Canran Wang, Yingjie Du, Yusen Zhao, Dong Wu and Shuwang Wu.

This research is supported by a National Science Foundation CAREER award as well as awards from the Air Force Office of Scientific Research and the Office of Naval Research.