Casting super strong metals with grain sizes down to nanometers during slow cooling. The study was published in Science Advances

For several years, Professor Xiaochun Li has been incorporating dense nanoparticles to make materials stronger and tougher – for example lightweight aluminum alloys and more recently, glass and ceramics. But those enhancing qualities take effect when the material is in its final form.

Li started to wonder, “what if nanoparticles could help make super strong metals, during the actual formation?” That is during casting, when they solidify from a hot molten liquid in a mold.

That could be a major breakthrough in the casting of metals, a process that is thousands of years old.

At the atomic level, atoms of metals group together to form crystal lattices. Those lattices then form units are known as crystalline “grains.”

“A grain is kind of like a little family of atoms that are ordered in lattice structure,” Li said. “Metals in their solid form are made up of these many families – each grain has its atomic lattice oriented in one direction, while its neighbors will be ordered in other directions.”

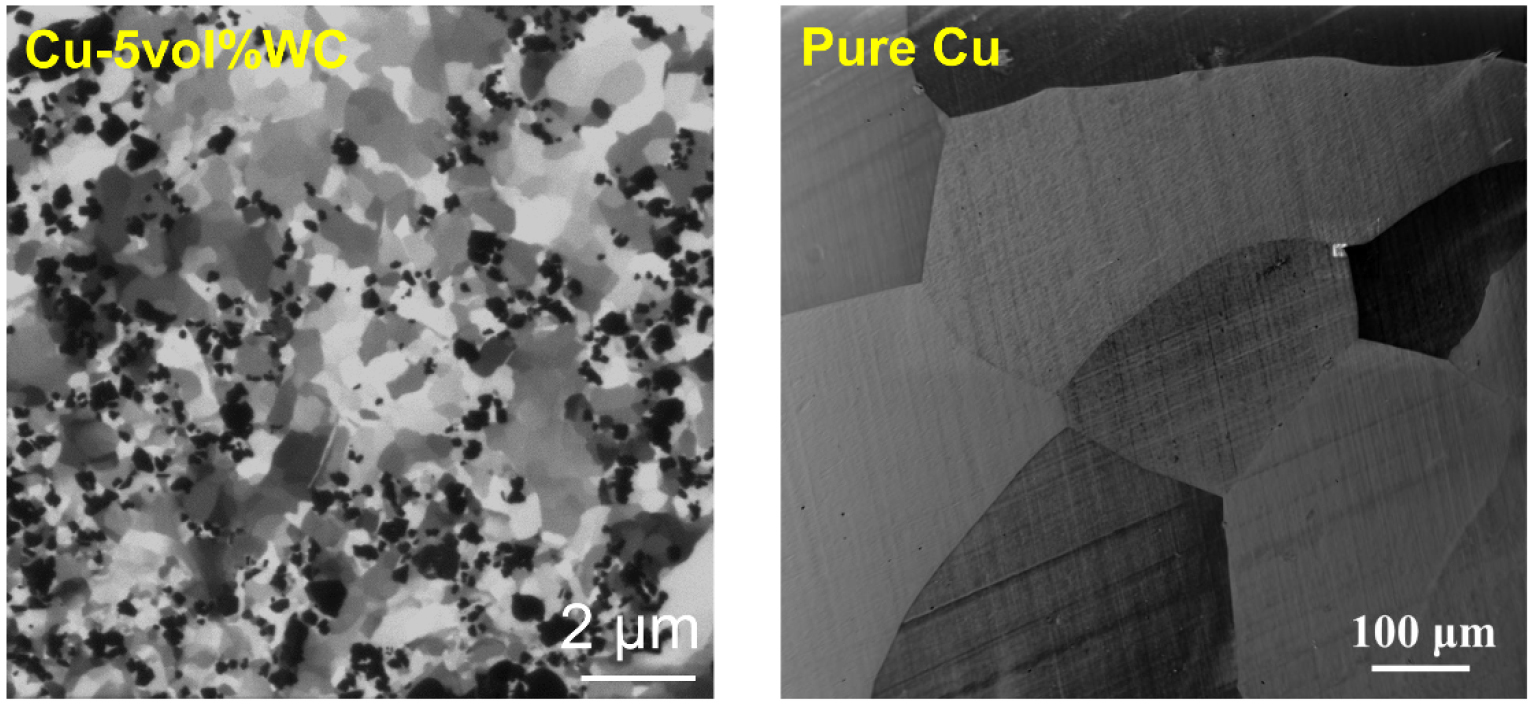

Looking through a microscope, they look similar to a granola bar or a puffed rice marshmallow treat.

“The smaller the grain sizes, the stronger a metal gets,” Li said. “The key is that boundaries between the grains form what’s essentially a network of scaffolding.”

A denser scaffolding network, makes a stronger metal. Typically, grain sizes are tens to hundreds of micrometers in diameter. If the grain sizes are at ultrafine sizes (less than one micrometer in diameter, or one-thousandth of a millimeter) or down to the nanoscale (less than 100 nanometers, or ten -thousandth of a millimeter), metals could have strength levels much stronger than their counterparts cast by the current methods.

A stronger structure means less material can be used for the same desired strength, thus improving energy efficiency, said Li, the Raytheon Professor of Manufacturing at the UCLA Samueli School of Engineering.

When liquid metals are cast, these grains start forming as it cools. Atoms travels quickly to form a solid tiny clusters in the hot liquid metal – a process called nucleation.

Currently, grains can only be kept small down to ultrafine or nanoscale using specialized rapid cooling equipment that cools at a rate of tens of thousands to millions of degrees Kelvin per second. However, this method only produces thin metals of tens of micrometers thick, making it impractical for industrial manufacturing.

Typically, in manufacturing, metals and metal alloys like steel cool at rates closer to 100 degrees per second at their fastest. These slow rates make impossible to cast bulk metal grain sizes down to ultrafine or nanoscale sizes.

Li found that the ceramic nanoparticles that he’s been working with to toughen materials could also make a fundamental change during casting and solidification – one that keeps grain sizes down to nanoscales without relying on rapid cooling. And, it could be possible to cast large pieces – steel beams or aluminum panels, for example. He and his colleagues published their study in Science Advances.

“What’s happening is that these tiny particles stop the grains from expanding too much,” he said. “The grains want to grow fast, but they keep bumping into these nanoparticles that won’t let them grab their smaller neighbors. This restricts the grain size. What ends up happening now is that there are many more tiny grains forming and much more boundaries in the same volume.”

The researchers demonstrated they could achieve grains that are less than a few hundreds of nanometers in diameter, about a few hundreds of times smaller than the smallest grain sizes achieved using conventional casting methods.

Using tungsten carbide particles, they cast ingots of copper that resulted in grain sizes at less than 200 nanometers, which is more than 1,000-times smaller than grains in conventional casting. They found similar results in zinc and aluminum.

The tested the strength of the copper and found it increased in strength 4.6 times from a normally caster counter

They also used particles of the titanium diboride, a ceramic, to cast an alloy of aluminum with ultrafine grains.

The lead author on the study is Chezheng Cao, a former doctoral student in Li’s Scifacturing Laboratory at UCLA.

Other authors of the study are graduate students Gongcheng Yao, Lin Jiang, Maximilian Sokoluk, Abdolreza Javadi, and Zeyi Guan; research scientist Igor De Rosa, all of UCLA; UC Irvine graduate student Xin Wang; Enrique J. Lavernia and Julie M. Schoenung, both professors of materials science at UC Irvine; Jim Ciston, a staff scientist at Lawrence Berkeley National Laboratory; and Weiguo Xie, a senior lecturer in mineral processing of the University of Exeter, U.K. Li holds UCLA faculty appointments in mechanical and aerospace engineering, and materials science and engineering.

The research was supported by the National Science Foundation, the Army Research Office and the U.S. Department of Energy’s Office of Science.